JACK FRAME REQUIREMENTS

The following design requirements will be met in our initial design

-

This jack frame must weigh under 50-lbs to ensure the user can position it under the car with ease.

-

The jack frame will also have a maximum compressive strength of 5000-lbs to ensure it will safely lift the rear/front end(s) of the vehicle without failure.

-

In addition the pins in the device arms need to move freely and support up to 2500-lbs per pin.

-

The jack frame must have a horizontal distance of less than 4 feet to universally fit under any type of standard vehicle.

-

The frame must deflect less than 1.0” when subjected to the 5000-lb loading.

-

The frame must have a collapsed height of less than 6 inches to sufficient fit under the chassis of most vehicles.

-

The entire system must cost under $1000.00 to manufacture, this includes all hydraulics, and frame components (project as a whole)

HYDRAULIC REQUIREMENTS

-

The powertrain system of this auto-jack must weigh less than 60lbs.

-

The powertrain system of this auto-jack system must be capable of lifting a 5000lb vehicle.

-

The powertrain system of this auto-jack must lift the vehicle at a rate of 1in/second.

-

The pneumatic portion of this auto-jack will require a maximum of 10CFM of air from a compressed air source.

-

The automatic locking safety pin of this auto-jack must be capable of supporting a 5000lb load independently.

EXAMPLE FRAME STRESS ANALYSIS

-

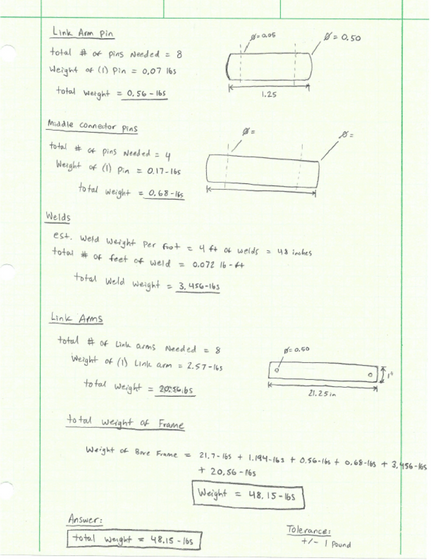

The frame is composed of AISI 1020 square stock; this material was selected using an appropriate decision matrix. This material was chosen because of its weight to strength ratio and the overall availability and cost of material. The analysis process below shows how the thickness of the material was determined.

-

Requirement:

The upper/lower frame must support a maximum compressive loading of 5000-lbs.

-

Analysis:

Since the upper frame needs to support a maximum loading of 5000-lbs, it was necessary to calculate the reactionary forces in the frame. It can be assumed that since it is a distributed load there will be two 2500-lb vertical forces (y-direction) directly on where the link arms are mounted to the upper frame.

-

Design Parameters:

The thickness including the safety factor of 1.5 was calculated to be 0.01026, which isn’t a standard thickness of square stock. So a standard thickness will be used of 0.120. This means the final dimensions of square stock needed to support the 5000-lb loading is 1” x 1” x 0.120”.

-

Documentation:'

The force analysis and thickness of square stock needed can be found in Appendix A-4, and the part drawing can be found in Appendix B-2.

**More analyses can be found In the